So after adding a little more power to my NG 9-5 Aero by way of a tune from Vermont Tuning (from 300 HP to 330 HP), I figured if a little is good, more *must* be better? After all, how hard could it be…? I began my crusade much like the fabled Don Quixote, who was determined revive chivalry and serve his nation. I was equally determined to get my portly sports sedan to perform like a younger, fitter, version of itself!

After my trip to the dyno, one thing that stuck out was the scorching high Intake Air Temps (“IAT”) and the accompanying very rich Air Fuel Ratio that was the result of the car trying to protect the engine and catalytic converters. Getting the IAT down is a common theme for all boosted motors. While there are vendors that do provide upgraded intercoolers for Saabs, and even Saab 2.8 V6 motors, they are all for the 9-3 and not the NG 9-5. So I figured on doing a custom intercooler setup. And in typical Josh-fashion, I decided to just start taking things apart… Now, I know what you’re thinking: “This will be a trainwreck of epic proportions…”, but you don’t know that! This could be great! Maybe…?

First up was to pop off the front bumper cover. What appears to be a big bottle brush is actually your power steering cooler. It doesn’t look terribly effective, so that could be a candidate for an upgrade. So that got drained down and moved out of the way. Next up was to pop out the old intercooler, but a small catch: it’s actually sandwiched in between a very hot radiator and the also not-cold A/C condenser, so no surprise that the IAT were so high. I disconnected the air plumbing that comes from the turbo, then the other side that feeds the motor. Surprisingly, there was a fair amount oil residue in the piping, so perhaps a catch can is in order down the road.

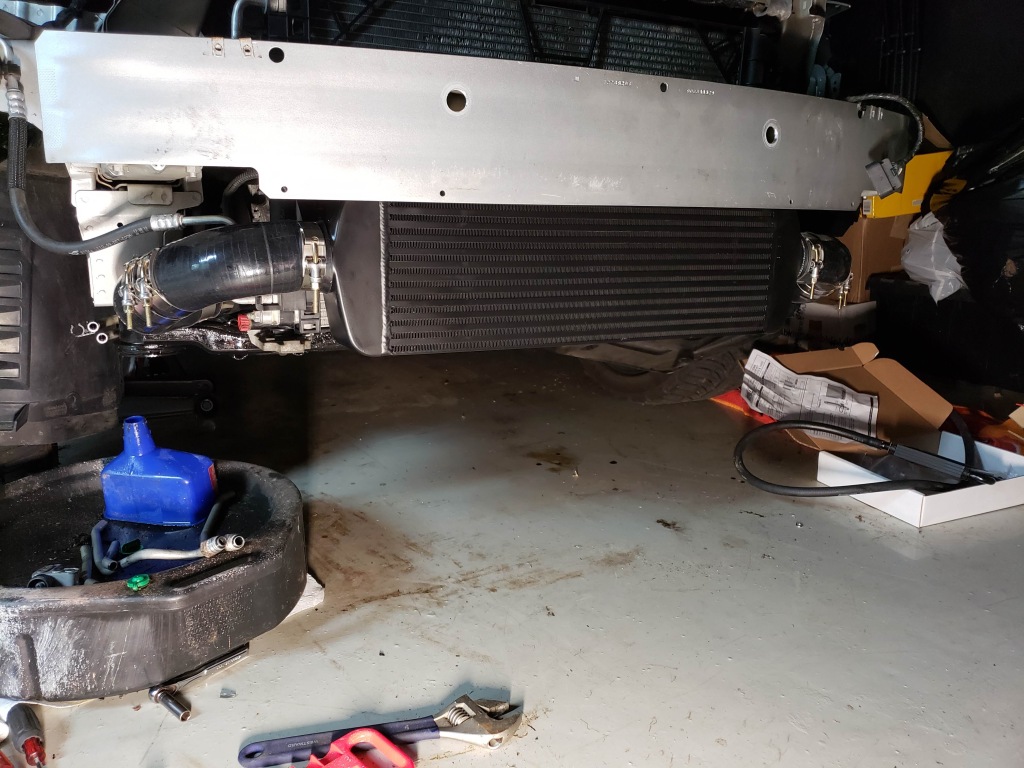

Since there were no off-the-shelf options, I started looking around at intercoolers and decided on the Mishimoto J-Line universal unit. Supposedly one of these intercoolers were in operation on a 500 HP car of another make, and it looked like I could fit it up in place of the existing power steering cooler that would need to be relocated. When the Mishimoto arrived, I mocked it up into place but still needed a way to secure it. My brother Jake came to the rescue with a design for some stainless sheetmetal that could be cut out, bent, and welded up into a beefy bracket. My workplace was then recommissioned from actually making us money, into parts fabrication for yet another Saab in my stable. Thankfully my boss does not read this blog…! The finished mounts were exactly what was needed, and I was able to hang the intercooler off the back side of the crash bar. I was able to source some silicone hoses to adapt the new intercooler to the existing hoses.

Next up is the biggest disaster since the Exxon Valdez… (I KNOW, YOU SAID THIS WOULD BE A TRAINWRECK, I GET IT!). The intercooler was actually not a bad project. Where things went sideways, was…the power steering. Yep, a mundane upgrade made this one of the worst projects of all time. I started with an off the shelf power steering cooler upgrade. I found a spot to hang the cooler, used the provided hoses to connect to the factory lines (that I had cut), and filled the system. I finished putting the car back together and started it up. I then went to back the car out of my garage for a test drive, and… oil slick! Power steering fluid everywhere! The hoses had popped off the OEM lines….

So I took the front bumper cover off, and bought new hoses and better quality clamps. I put everything back together…and oil slick #2…!?! After seeing that the hoses wouldn’t stay on the OEM lines, I decided to beef it up by getting 3000+ PSI adapters for the OEM lines that would allow me to push the hoses onto an actual hose barb, and then I hooked the hoses up to that. I refilled everything and fired up the car… oil slick #3… Unf#$%king real!?!

I sourced a high pressure oil cooler used in Mustang Cobras that race on road courses, all TIG welded. I then took my heavy-duty adapters, added 2500 PSI Teflon hoses up to the cooler. This time I had it for sure! I refilled the system, and had my wife turn the wheels while I watched, and… the new oil cooler blew out, spraying power steering fluid into oil slick #4… You literally cannot make this up… I decided to let the car sit (after cleaning up yet another round of power steering fluid) and did some homework on the OEM power steering system design. After pulling the factory schematics and following all of the lines, it hit me: this system was 180 degrees different from every other power steering system I had ever seen. Instead of cooling the fluid on the return (after the high pressure was used by the power steering rack), the NG 9-5 cooled the fluid on the SUPPLY side feeding the rack!?! No off the shelf cooler would cut it at these pressures (around 2000 PSI). I’ve never seen a car (or truck) operate a power steering cooler setup like that. And, given that most cars now have electric power steering, we probably never will again.

So, I dug back into the Grainger catalog yet again, and bought some more 3000# adapters (only $50.00 per fitting…lol). After all of this messing around, I ended up reinstalling the OEM cooler… What a mess of time and money wasted, not to mention absorbant shop towels… Unfortunately, like Don Quixote, I had seen my Saab’s power steering system as the way I *thought* it should be, instead of doing my typical homework first. My results were similar: he joisted against a windmill that couldn’t be defeated and I railed against a positive displacement pump that wasn’t taking no for an answer.

So, with yet another top off of the power steering system, I reassembled the car and finally took it for a test drive! Instead of IATs of 45-50 degrees over ambient temps, my IATs were now 15-20 degrees over ambient. A much needed improvement! Now if only I had something to improve my power steering induced PTSD…